Page 1 of 1

minimum tailshaft yoke clearance ?

Posted: Wed Jul 16, 2014 10:28 pm

by niterida

Hi guys - just wondering what is the minimum clearance I could get away with when fitting a one piece tailshaft. If my calculations are correct a 6speed shaft will be 20mm longer than the ideal length for my Brumby conversion. Now I can tweak the wheel base a little (say 5-10mm) so the shaft will be 10-15mm longer than ideal. Now this will mean that the yoke in the rear of the box will not have as much room to move forward before it hits the box and binds up. But since the box and diff are both rigidly mounted (and more rigid than standard due to stiffer bushings and mountings that I am using) will this be an issue ?

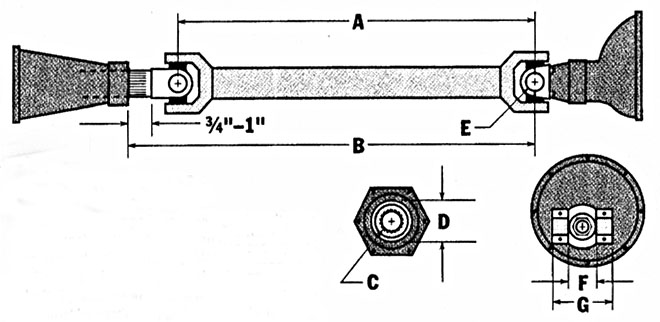

The 3/4-1" shown on this diagram is the clearance I am talking about :

http://www.hotrodhotline.com/md/html...aft_basics.php

but this tailshaft is for a live axle rear end where the diff moves substantially - hopefully I can get away with 10mm ???

Posted: Thu Jul 17, 2014 5:37 pm

by niterida

No one have any ideas ?

Posted: Thu Jul 17, 2014 6:40 pm

by Venom

I aimed for between 10-15mm clearance when I had the tailshaft made to suit the L series rear housing in my last gearbox. It was 2 piece though and I, like you, had no idea on the minimum it just seemed like a good target.

Posted: Thu Jul 17, 2014 6:49 pm

by niterida

Yeah I reckon with an IRS (fixed diff) and stiffer mounts I can get away with 10mm and I can get that by moving my rear crossmember / diff back about 10mm.

4WD Shaft ...

Posted: Fri Jul 18, 2014 1:03 am

by Bantum

Not sure on minimum 'yolk' distance, but if you can get the shaft to fit without binding on anything - should be good ...

Image you referenced above :

The service book I've got says the distance between joints (A) on the prop shaft for Station Wagon & Brumby should be 1136 mm ... ( 44.72 in )

However in this case you have later model diffs, so would have to measure what you have ended up with to workout what it should be ...

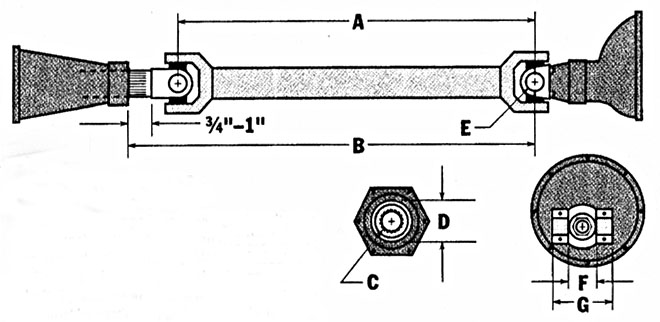

& this one for general reference :

To me, Tube runout & axial play would be the more important checks to make to ensure smooth operation + less flex in shaft ...

Hence later models going to a two piece system ...

Cheers, Bantum ...

Posted: Fri Jul 18, 2014 7:00 am

by niterida

I just realised that I will have to get a custom or shortened shaft - even if the 6 speed/auto shafts fit they ar the wrong splines for my 5 speed box