I have mocked up with two of the three MY bolts (the two that screw in to the suspension bracket (I listed it as one blind and two through-with-nuts, it's actually the other way around) line up) :

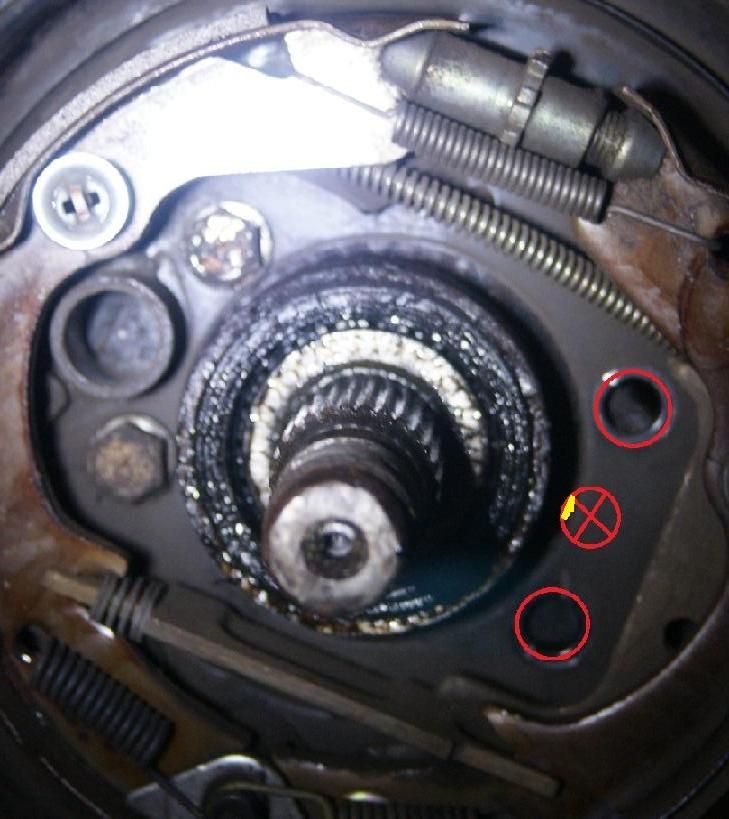

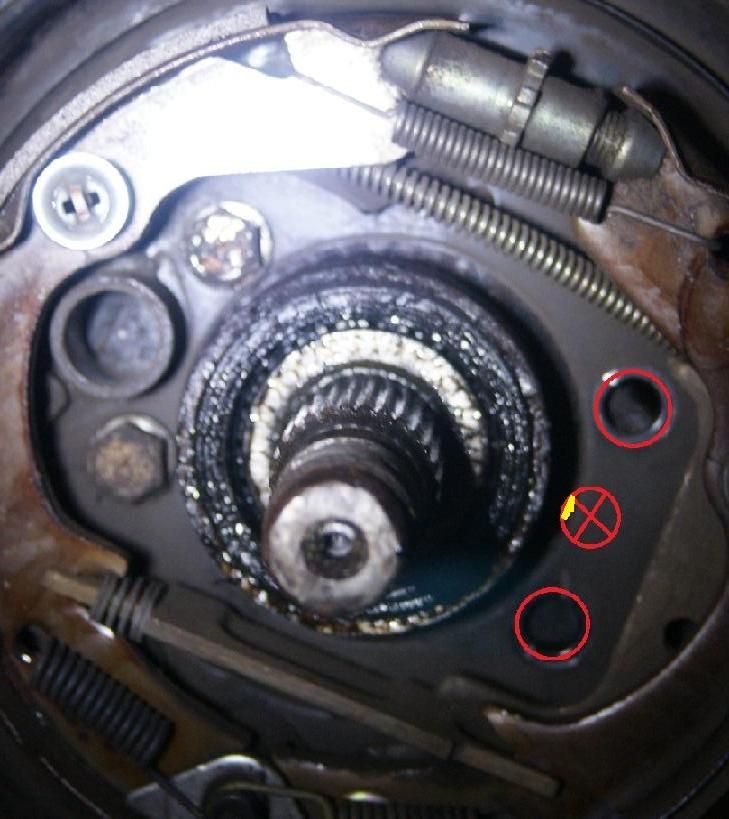

There are two options I can see. One is use either (or both) of the (brake side) holes, and drill through the (suspension side) bracket - which isn't ideal as (a) the bracket is pretty heavy gauge but more importantly (b) there isn't full material on the back (you can see on the top red circle that the top 40% from the top right corner is just thin air). Option two is to use the (suspension side) hole and drill a matching hole in the (brake side) bracket. Again, there isn't 100% material coverage (the yellow area inside the red circle with the diagonal lines through it has no metal), but I think it is better than option one.

Next issue is the hand-brake cable is right up against the suspension bracket :

I think this is ok, as it needs to stay away from the wheel itself.

So, I continued the mock-up with the two bolts only attached (and haven't refitted the calipers), and there is a bit of a gap between the hub and the backing plate. The rust marks on the XT6 hub seem to indicate this is same as factory :

And now with the disc fitted :

The position of the caliper is a bit of a concern, as it's basically in the 4 o'clock position. I would have been happier in the 3 o'clock but I think it's ok.

And a shot of the mock up complete (sans caliper), except taken from the back of the car to show the hand brake cable routing :

1989 Brumby - Shiny new red paint, stroked EJ20 phase 2 SOHC with Darton sleeves bored to EJ22, Wiseco high-compression pistons, Delta 2000 grind cams , EJ/XT6 5 stud with WRX 4/2 pots, 5-speed, 86 GTS seats and so much more.

Contact me for reproduction XT6 hubs...and EA82 rear discs.

:???:

:???: