I can see complete cars all the way through being fabricated soon out of titanium/plastic and ceramics coming from printers. I know of a guy that built a whole boat out of the stuff. Pretty cool.El_Freddo wrote:That's awesome ^ What's the cost?

And have you heard about the dude in NZ that's building his own Aston DB4 with a 3D printer?

...

He's also built a Ferrari 250 GT or something of the like...

Enjoy!

Bennie

3D Printers ...

- 60766244

- Junior Member

- Posts: 586

- Joined: Fri Nov 09, 2012 3:32 pm

- Location: Kalamunda, Western Australia

Otter the 2004 Outback with all the fruit.

Possible Improvements: Rigid 12db Phone Aerial Fitted, Air-compressor w/ Hose & Air-Tank, Jerry Holders, Lift, Nudgebar and Spots?

|| Ausubaru Wiki: New AUSubaru Wiki, About the Wiki || My Ex, Maple the Brumby, Rack, Lift Kit, Raptor-Liner Tray || Shed: Benches ||

Possible Improvements: Rigid 12db Phone Aerial Fitted, Air-compressor w/ Hose & Air-Tank, Jerry Holders, Lift, Nudgebar and Spots?

|| Ausubaru Wiki: New AUSubaru Wiki, About the Wiki || My Ex, Maple the Brumby, Rack, Lift Kit, Raptor-Liner Tray || Shed: Benches ||

- Bantum

- Senior Member

- Posts: 2022

- Joined: Sun Jul 29, 2012 4:30 pm

- Location: Northern Territory + QLD

- Contact:

Hmmm ...

Ha, got me thinking - Titanium subi engine ... !

I'm not sure if it would work though ... ?

Ciao, Bantum ...

I'm not sure if it would work though ... ?

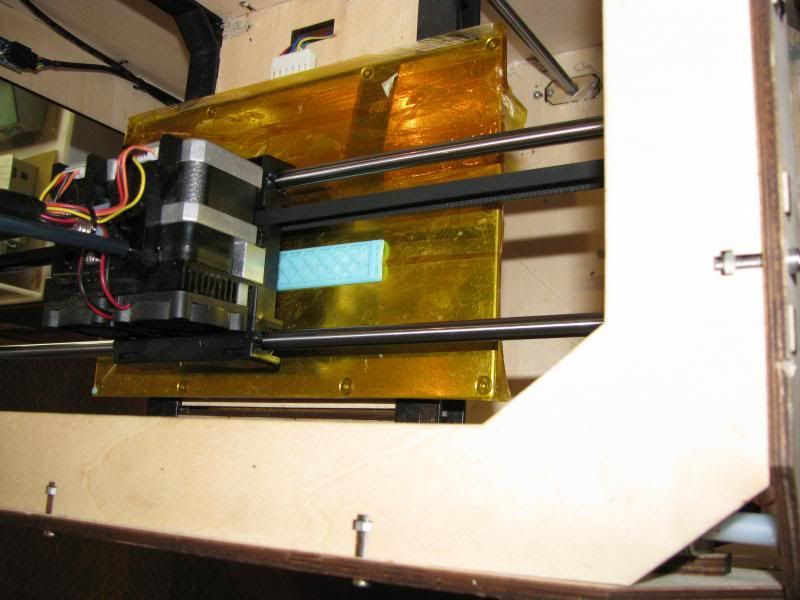

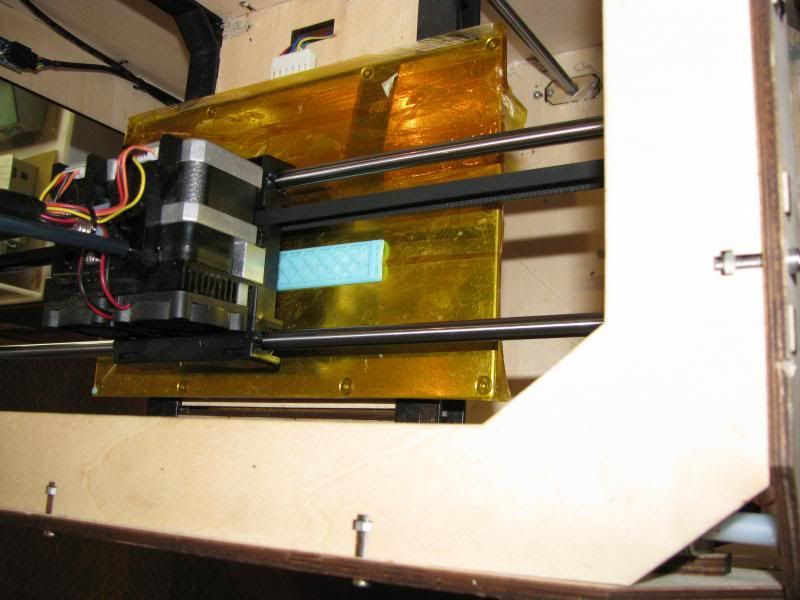

So far about $ 300 ( that's just for what's in the picture ) More to come on that ...El_Freddo wrote: ... What's the cost ... ?

Yep, sorry you beat me to it ...El_Freddo wrote: ... And have you heard about the dude in NZ that's building his own Aston DB4 with a 3D printer?

Ciao, Bantum ...

- Bantum

- Senior Member

- Posts: 2022

- Joined: Sun Jul 29, 2012 4:30 pm

- Location: Northern Territory + QLD

- Contact:

A small update ...

I have got myself a second 19" monitor ( free to boot ! ) & graphics card to enlarge the desktop 'work' space ...

While not directly related to the topic, it's progress towards getting a prototype printer sorted none the less ...

Should start getting all the printer bits together soon ...

Cheers, Bantum ...

While not directly related to the topic, it's progress towards getting a prototype printer sorted none the less ...

Should start getting all the printer bits together soon ...

Cheers, Bantum ...

- Bantum

- Senior Member

- Posts: 2022

- Joined: Sun Jul 29, 2012 4:30 pm

- Location: Northern Territory + QLD

- Contact:

gMax ...

Found a larger base printer :

Printer has a 40.6 x 40.6 x 22.8 cm build envelope & sells for approx. $1300 for the kit. However it has only recently come out of the USA, so is limited in supply.

More details can be found here : http://www.gmaxprinter.com/

http://www.3dprinterworld.com/article/g ... arter-goal

http://www.kickstarter.com/projects/168 ... int-bigger

It's closer to what I'm looking for, just have to work out the details now ...

Cheers, Bantum ...

Printer has a 40.6 x 40.6 x 22.8 cm build envelope & sells for approx. $1300 for the kit. However it has only recently come out of the USA, so is limited in supply.

More details can be found here : http://www.gmaxprinter.com/

http://www.3dprinterworld.com/article/g ... arter-goal

http://www.kickstarter.com/projects/168 ... int-bigger

It's closer to what I'm looking for, just have to work out the details now ...

Cheers, Bantum ...

G'day Guy's,

One of the projects I intend to do is turn that cnc I made into a 3D printer. I had a chat with my good mate who gave me that subi who is also an engineer about it and instead of using plastic wire using grated plastic. I explained my theory to him about how to go about it and he did say he would have a good think about and get back to me. I'm currently also making up a smaller cnc which I can give him to play with and when he has got some spare time along with myself my machineshop will be the place we make the prototype.

All of the reprap 3D printers use the arduino as the interpreter and some guy's have gone about using the pic micro's which I'm into. So given time this project will get under way and to date I haven't seen any 3D printer that uses grated plastic. The whole idea is with so much plastic wasted whynot utilize it for 3D printing.

One of the projects I intend to do is turn that cnc I made into a 3D printer. I had a chat with my good mate who gave me that subi who is also an engineer about it and instead of using plastic wire using grated plastic. I explained my theory to him about how to go about it and he did say he would have a good think about and get back to me. I'm currently also making up a smaller cnc which I can give him to play with and when he has got some spare time along with myself my machineshop will be the place we make the prototype.

All of the reprap 3D printers use the arduino as the interpreter and some guy's have gone about using the pic micro's which I'm into. So given time this project will get under way and to date I haven't seen any 3D printer that uses grated plastic. The whole idea is with so much plastic wasted whynot utilize it for 3D printing.

- Brumbyowner

- Junior Member

- Posts: 51

- Joined: Tue Sep 11, 2012 8:25 am

- Location: Tapping WA

Ahh!!

Finally some-one who understands the complexities and quality of Star Trek and what they may one day give us. Isnt it amazing that items thought of in Star Trek are actually coming true.

Finally some-one who understands the complexities and quality of Star Trek and what they may one day give us. Isnt it amazing that items thought of in Star Trek are actually coming true.

60766244 wrote:I'd love one too! But building one myself is so time consuming, buying one is so wallet consuming! Maybe oneday

As for specialized materials you need specialized printers to do this. Thanks to companies like Defence Distributed in the US (Specializing in open-source gun printing) there's a lot of carbon-based and other types of printable in development.

Exciting times for home manufacturing ahead.

Personally: I'm keen on a star-trek level replicator.

I recently met a German couple touring Oz in a troopy and the guy was a mad 3d printer dude. Used his to make helicopter drones. Any way he prints the parts of his 3d printer and sends them anywhere for 200euro's said you need 2 other parts to get it to work a motor and the arm. I can ask him for more info if anyone is keen.

He also printed 3 wheels for my dishwasher that where missing hahaha

He also printed 3 wheels for my dishwasher that where missing hahaha

Fused deposition printing is still in its infancy. It's no where near "plug and play". You can get some pretty successful prints with cheap systems but it's touch and go weather your designed part will print right or not. If you have a printer to print parts that you design yourself you will find you learn quirks of your printer and design around them. It is a lot of fiddling working out what software/firmware to use with your setup. And then you get into different options in your gcode generator such as infill, support, etc. It is not for the light hearted. And it is not for someone who does not understand programming or electronics and electricity.

Saying all that, you don't have to be a programmer, or an electrician. But having a basic understanding of programming logic is pretty essential. And knowing how electricity flows and reacts through components such as resistors, capacitors, inductors, transistors and FET's is pretty useful to avoid many hours spent aimlessly trouble shooting.

I built a Prusa i1. I bought a plastic printed parts kit online. I bought experimental Gen 7 electronics from the maker in Denmark. I bought Nema 17 steppers from ebay along with the Pololu/Stepsticks stepper drivers. I bought the heated bed from ebay also (most of this stuff came from overseas). All my hardware came from either SmallParts.com.au or Coventry Fasteners.

All up I spent around the $680 mark and I did it on the cheap! That was at the beginning of last year, so prices have dropped. You can now build a Prusa i2 for around $500 I have heard...

There are three filaments you can use at the moment off the shelf. PLA (poly lactic acid) which is made from sugar using a catalyst. ABS and Nylon.

ABS requires a heated bed and warps a lot of anything larger than around 80 x 80mm (but completely depends on model design and dimensions such as thickness, solidness and height).

Nylon is a new option. It can print on non heated bed (best in a glued down fabric I have seen). It comes out flexible like you would expect.

PLA is hard and brittle but needs much lower temps for both the built platform and print head. It is also biodegradable and will lose form in hot temps around the 70c mark.

I don't see a point in a FDM (fused deposition modeling) printer with a bed size over 250mm x 250mm. Warpage even with PLA is too excessive for sizes over that size.

Going cheap on parts has caused me many headaches. Mostly with the electronics. I bought cheap stepper drivers and wish I just spent twice the amount on the proper branded Pololu's. Also going with the Gen 7 meant I had a hard time moving over from Teacup firmware to Marlin firmware.

I wanted to use Marlin because it had what they call "look ahead" which basically makes it so the printer doesn't have to decelerate to a stop at every change of direction; this stopping and starting happens so fast you can't see it, but around corners it is enough time for the print head to bleed a little and cause over sized edges.

To give you an idea of the electrical knowledge needed to change the firmware from Teacup to Marlin I had to change an inductor, cut circuit tracks and run new wires to create alternative paths for the temp sensors power.

To sum up my printer.

I have a Prusa i1

Gen 7 v1.3 modded to v1.4.1

Marlin firmware

Using Slic3r and Printrun on Windows 7

J-head Mk 5b print head mounted on a Gregs extruder

Nema 17 steppers and GT2 belts

Metric M8 frame with stainless steel Z axis rods

Have a look at my thingiverse profile to see some of the things I have designed and printed, and things I have downloaded and printed. http://www.thingiverse.com/Phizinza/designs

Saying all that, you don't have to be a programmer, or an electrician. But having a basic understanding of programming logic is pretty essential. And knowing how electricity flows and reacts through components such as resistors, capacitors, inductors, transistors and FET's is pretty useful to avoid many hours spent aimlessly trouble shooting.

I built a Prusa i1. I bought a plastic printed parts kit online. I bought experimental Gen 7 electronics from the maker in Denmark. I bought Nema 17 steppers from ebay along with the Pololu/Stepsticks stepper drivers. I bought the heated bed from ebay also (most of this stuff came from overseas). All my hardware came from either SmallParts.com.au or Coventry Fasteners.

All up I spent around the $680 mark and I did it on the cheap! That was at the beginning of last year, so prices have dropped. You can now build a Prusa i2 for around $500 I have heard...

There are three filaments you can use at the moment off the shelf. PLA (poly lactic acid) which is made from sugar using a catalyst. ABS and Nylon.

ABS requires a heated bed and warps a lot of anything larger than around 80 x 80mm (but completely depends on model design and dimensions such as thickness, solidness and height).

Nylon is a new option. It can print on non heated bed (best in a glued down fabric I have seen). It comes out flexible like you would expect.

PLA is hard and brittle but needs much lower temps for both the built platform and print head. It is also biodegradable and will lose form in hot temps around the 70c mark.

I don't see a point in a FDM (fused deposition modeling) printer with a bed size over 250mm x 250mm. Warpage even with PLA is too excessive for sizes over that size.

Going cheap on parts has caused me many headaches. Mostly with the electronics. I bought cheap stepper drivers and wish I just spent twice the amount on the proper branded Pololu's. Also going with the Gen 7 meant I had a hard time moving over from Teacup firmware to Marlin firmware.

I wanted to use Marlin because it had what they call "look ahead" which basically makes it so the printer doesn't have to decelerate to a stop at every change of direction; this stopping and starting happens so fast you can't see it, but around corners it is enough time for the print head to bleed a little and cause over sized edges.

To give you an idea of the electrical knowledge needed to change the firmware from Teacup to Marlin I had to change an inductor, cut circuit tracks and run new wires to create alternative paths for the temp sensors power.

To sum up my printer.

I have a Prusa i1

Gen 7 v1.3 modded to v1.4.1

Marlin firmware

Using Slic3r and Printrun on Windows 7

J-head Mk 5b print head mounted on a Gregs extruder

Nema 17 steppers and GT2 belts

Metric M8 frame with stainless steel Z axis rods

Have a look at my thingiverse profile to see some of the things I have designed and printed, and things I have downloaded and printed. http://www.thingiverse.com/Phizinza/designs

Owned - 89 Brumby, 83 Wagon, 83 Leone 4WD Sedan, 83 Touring Wagon, 99 Outback

Own - 87 Brumby, 93 Liberty, 09 Forester

Offroading Subarus Facebook Page

Own - 87 Brumby, 93 Liberty, 09 Forester

Offroading Subarus Facebook Page

- Bantum

- Senior Member

- Posts: 2022

- Joined: Sun Jul 29, 2012 4:30 pm

- Location: Northern Territory + QLD

- Contact:

OOoo - thanks Phizinza, interesting read + great site you have there ...

Yeah I was looking to get a base big enough to print architecture models etc. A4 to A3 size, hence requirement for a larger machine ...

I'm still weighing up my options, but with new tech coming out all the time I might just wait a bit to see where its going before committing to getting one ...

The LIX pen just might be a interim alternate if I can get on to play with ...

Cheers, Bantum ...

Yeah I was looking to get a base big enough to print architecture models etc. A4 to A3 size, hence requirement for a larger machine ...

I'm still weighing up my options, but with new tech coming out all the time I might just wait a bit to see where its going before committing to getting one ...

The LIX pen just might be a interim alternate if I can get on to play with ...

Cheers, Bantum ...

- steptoe

- Master Member

- Posts: 11582

- Joined: Thu Oct 06, 2005 10:00 am

- Location: 14 miles outside Gotham City

dawned on me that the component I was looking at with its funny fine lines along it was likely a 3D printed component made up to feed air for interior from the grille below windscreen and with its special computer designed ? shape - clear the 3.8 litre V6 in an engine bay of a Triumph Dolomite where a 1.8 or 2.0 once sat. Pretty awesome stuff this technology !

- Silverbullet

- Senior Member

- Posts: 2946

- Joined: Mon Aug 23, 2010 6:20 pm

- Location: Adelaide

Something nobody has mentioned yet; software. Specifically the toolpath generating software. It's all well and good having the machine and hardware to print whatever you want but what are people using for the 3D CAD modelling and the program to turn that model into a usable toolpath? Is there a free program out there capable of drawing complex 3D shapes? AutoCAD doesn't count (not free and useless for 3D modelling) And a free CAM program to go with it? Because writing the code out manually for a 3D shape is ridiculously time consuming and difficult for anything other than circles and squares.

I'm completely out of the loop with home made CNC and 3D printing stuff, so apologies if I sound ignorant

I'm completely out of the loop with home made CNC and 3D printing stuff, so apologies if I sound ignorant

Will it ever end!?

-EA81 TWIN CARB!!!!

-L series 5 speed

-Custom paint job

-2" lift

-Full custom re-wire

-L series front end

-EA81 TWIN CARB!!!!

-L series 5 speed

-Custom paint job

-2" lift

-Full custom re-wire

-L series front end

- Bantum

- Senior Member

- Posts: 2022

- Joined: Sun Jul 29, 2012 4:30 pm

- Location: Northern Territory + QLD

- Contact:

More 3D Printing ...

Went to the train Show here in Brissy recently saw this on display :

& in motion :

In speaking to the owner, said it cost him about $ 1700 to set up ( had assemble it too ) & came with its own operating system ...

Forget the name of file it needs to print, but all you need to make it work apparently is a *.dxf output file from a CAD program ( with X,Y & Z coordinates ), plug it into the converter program and it will work out the slicing required to print in layers.

I might see if I can get some prints from him ...

Cheers, Bantum ...

& in motion :

In speaking to the owner, said it cost him about $ 1700 to set up ( had assemble it too ) & came with its own operating system ...

Forget the name of file it needs to print, but all you need to make it work apparently is a *.dxf output file from a CAD program ( with X,Y & Z coordinates ), plug it into the converter program and it will work out the slicing required to print in layers.

I might see if I can get some prints from him ...

Cheers, Bantum ...

- Bantum

- Senior Member

- Posts: 2022

- Joined: Sun Jul 29, 2012 4:30 pm

- Location: Northern Territory + QLD

- Contact:

K8200 ...

I passed by Jaycar the other day & saw this on sale for $1,299 :

More details here : http://www.jaycar.com.au/productView.asp?ID=TL4020 & yes they sold Plastic filament - Black PLA & ABS for about $43 a roll ...

They are getting cheaper - Do you recon if I wait a bit longer the price will come down further ?

Very tempted to get one ...

Cheers, Bantum ...

More details here : http://www.jaycar.com.au/productView.asp?ID=TL4020 & yes they sold Plastic filament - Black PLA & ABS for about $43 a roll ...

They are getting cheaper - Do you recon if I wait a bit longer the price will come down further ?

Very tempted to get one ...

Cheers, Bantum ...

- Bantum

- Senior Member

- Posts: 2022

- Joined: Sun Jul 29, 2012 4:30 pm

- Location: Northern Territory + QLD

- Contact:

The Cube ...

Well I'll be :

More info here : Cube 3D Printer

$ 699 + comes in Silver, Pink & Blue too ... ! Getting closer to my price range - although I'm entirely not sure if this would be suitable - but worth noting anyways ...

Cheers, Bantum ...

More info here : Cube 3D Printer

$ 699 + comes in Silver, Pink & Blue too ... ! Getting closer to my price range - although I'm entirely not sure if this would be suitable - but worth noting anyways ...

Cheers, Bantum ...

- Bantum

- Senior Member

- Posts: 2022

- Joined: Sun Jul 29, 2012 4:30 pm

- Location: Northern Territory + QLD

- Contact:

Spark ...

Bit of an Update :

Autodesk have announced they are developing Open 3D printer software ( compatible with AutoCAD naturally ), it will be interesting to see where this leads ...

Not much detail on their printer yet, but here's something to wet your appetite :

More info here : http://spark.autodesk.com/

Add : http://3dprint.com/16422/autodesk-spark-3d-printing/

I sure some of you have seen this too :

& is a result of Spark tech apparently ...

More reading here : http://news.autodesk.com/press-release/ ... orate-firs

and here : http://www.3dmag.it/autodesk-local-motors-spark/

I reckon were not far away from the idea of ordering what car you want & getting it printed on the spot ...

Cheers, Bantum ...

Autodesk have announced they are developing Open 3D printer software ( compatible with AutoCAD naturally ), it will be interesting to see where this leads ...

Not much detail on their printer yet, but here's something to wet your appetite :

More info here : http://spark.autodesk.com/

Add : http://3dprint.com/16422/autodesk-spark-3d-printing/

I sure some of you have seen this too :

& is a result of Spark tech apparently ...

More reading here : http://news.autodesk.com/press-release/ ... orate-firs

and here : http://www.3dmag.it/autodesk-local-motors-spark/

I reckon were not far away from the idea of ordering what car you want & getting it printed on the spot ...

Cheers, Bantum ...