Work has finally started in earnest. I have 2 weeks off and am hoping to get a lot done. Started off by sussing out how to mount the WRX suspension front and rear. Turns out the front crossmember puts the mounting bolts right on the edge of the chassis rail and the lower control arm rear mounts right in the middle of the chassis rail where it starts to come up from the cabin floor. To make it fit would have required major cutting of the chassis which is a total no-no if I want to get it legally registered. So hit a major hurdle on my first thing I started

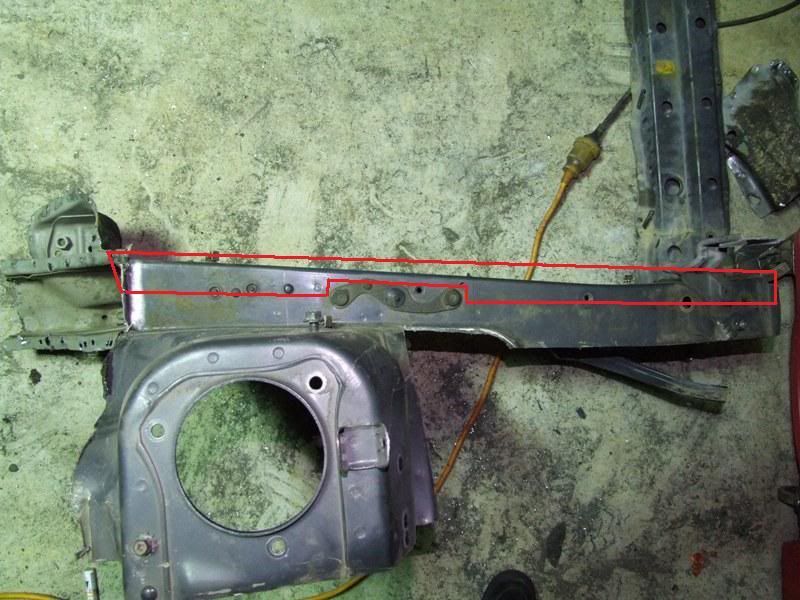

Did lots of head scratching and looking and thinking and finally came up with a solution. Turns out the kind people at Subaru made the Brumby crossmember with mounting points to fit the lower control arm exactly in the right spot in relation to all the other important bits like the position of the crossmember itself, the steering and the struts. So I am going to use the Brumby crossmember and everything else will be WRX stuff. This only needs a mount made up for the rear of the lower control arm - will cut this out of the donor car and weld it on and will hopefully look like it is there from the factory. The other major challenge with this set up is the CV shafts - they need to be about 60mm shorter so I will have to get custom ones made up.

But on a plus side it means my track will be about the same and means I don't need to flare my guards.

The rear is a lot easier to do. The diff crossmember just needs about 5mm cut off the ends and will bolt up to the chassis rail. Well it will after I put some new captive nuts inside the chassis itself. The front T piece that holds the front of the diff up will need to be narrowed and the mounts brought in about 100mmm either side and mounting brackets nmade up to run on the inside of the chassis rails and the mounts for the rear trailing arms will line up on the chassis so again just need to weld some captive nuts (might need a bit of massaging of the chassis rail).

This would all fit as described but would then leave me with much wider track at the rear so I will need to get shorter rear control arms. Can do this by cutting and welding or hopefully getting some adjustable ones (if they can adjust far enough). And of course will need shorter CV shafts as well.

Nice lightweight BBS wheel mounted and looking good :

WRX lower control arm and coilover mounted on Brumby crossmember :

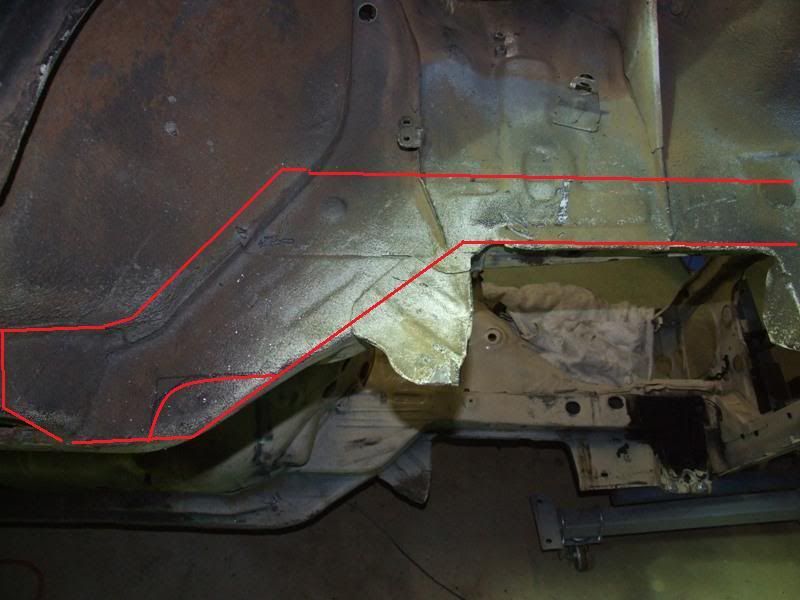

Here you can see where the rear mount for the lower control arm needs to be made :

And a shot from below :

And one form in the engine bay :